Understanding Wood Cut Orientations

Before discussing veneer, it is important to clarify two key ways a log can be cut, which affect the veneer’s grain orientation and properties:

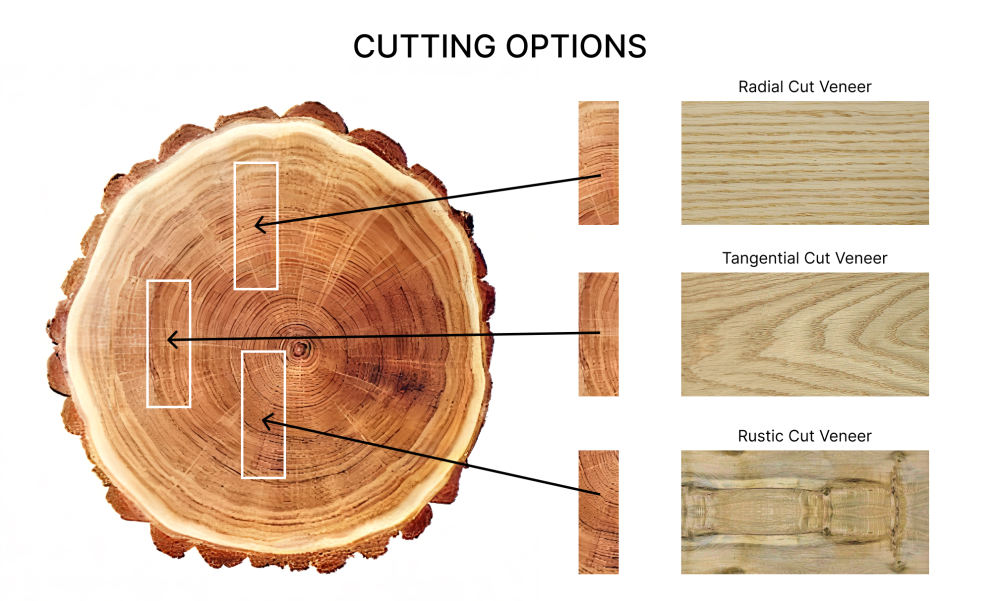

- Radial Cut (Quarter-Sawn): A cut made through the log’s center (the pith), along the radius. The cut plane passes through the tree’s heart. Veneer sliced this way is called radial veneer. It features growth rings that intersect the board’s surface at high angles, typically 60–90°. This yields a very straight, uniform grain pattern.

- Tangential Cut (Flat-Sawn): A cut made parallel to a tangent of the growth rings, at some distance from the center. The cut plane is offset from the pith. Veneer from this cut is called tangential veneer. Here the growth rings meet the board’s surface at a low angle (usually less than 45°), producing a pronounced arched or “cathedral” grain pattern.

Radial Cut Veneer

Radial-cut veneer (quarter-sawn veneer) is valued for its uniform texture and stability. Because the slicing is done through the log’s center, the resulting veneer has a very even, linear grain. The spacing between annual rings on the surface is minimal, yielding a consistent color and figure.

Radial veneer is resistant to external influences – it does not deform easily with changes in humidity or temperature and it wears well over time. In technical terms, radial-cut wood has a much lower tendency to shrink or swell compared to other cuts. For example, quarter-sawn oak boards have a shrinkage coefficient of about 0.19% (and swelling about 0.20%) in the radial direction, which is roughly half the values for tangentially cut wood.

Because radial veneer must be cut with the knife blade following the radius of the log, each veneer flitch is smaller and there is more waste. Despite the higher cost and lower yield, the technical advantages — superior strength, wear resistance, and low distortion — make radial cut veneer highly sought after for high-quality woodworking.

Tangential Cut Veneer

Tangential-cut veneer (flat-sawn veneer) is cut parallel to the growth rings, rather than through the center. This method yields a very pronounced grain pattern on the veneer. Tangential veneer often displays the familiar “cathedral” or wavy grain pattern of wood, with arched figures formed by the annual rings.

Tangential veneer typically has a less uniform appearance than radial veneer. Additionally, tangentially cut wood is less dimensionally stable. The shrinkage and swelling coefficients for tangential cut boards are higher – roughly double those of radial cut.

On the other hand, tangential cut veneer is much more economical. Because a log can be sliced tangentially with minimal waste (cutting parallel to the rings yields wider sheets and more veneer per log), the yield is higher and cost per square foot of veneer is lower.

In summary, tangential veneer offers bold, decorative grain patterns and affordability, at the cost of greater movement and slightly reduced structural uniformity.

Conclusion

Both radial and tangential veneers have their place in woodworking. Radial (quarter-sawn) veneer is prized for its straight grain, consistency, and superior stability – making it suitable for high-end, precision applications. Tangential (flat-sawn) veneer, with its striking grain patterns and lower cost, is often used for its beauty and economic advantages, especially in decorative surfaces.

Ultimately, the choice between radial and tangential veneer will depend on the priorities of a project. When stability, durability, and a uniform look are paramount, radial veneer is the top choice. When a bold wood texture or cost savings are desired (and a little movement is acceptable), tangential veneer may be preferred.

Radial and Tangential Veneer

Understanding Wood Cut Orientations

Before discussing veneer, it is important to clarify two key ways a log can be cut, which affect the veneer’s grain orientation and properties:

- Radial Cut (Quarter-Sawn): A cut made through the log’s center (the pith), along the radius. The cut plane passes through the tree’s heart. Veneer sliced this way is called radial veneer. It features growth rings that intersect the board’s surface at high angles, typically 60–90°. This yields a very straight, uniform grain pattern.

- Tangential Cut (Flat-Sawn): A cut made parallel to a tangent of the growth rings, at some distance from the center. The cut plane is offset from the pith. Veneer from this cut is called tangential veneer. Here the growth rings meet the board’s surface at a low angle (usually less than 45°), producing a pronounced arched or “cathedral” grain pattern.

Diagram of different lumber cut patterns. The cross-section of a log on the left shows the radial cut (through the center) and tangential cut (off-center, along the growth rings), as well as a rustic cut for comparison. The veneers produced from each type of cut are shown to the right.

In practice, natural wood veneer is sliced from logs according to these cutting orientations. The cut type influences the veneer’s appearance and its physical behavior (such as how much it shrinks or swells with moisture changes). Below we explore the characteristics of radial vs. tangential cut veneer in detail.

Radial Cut Veneer

Radial-cut veneer (quarter-sawn veneer) is valued for its uniform texture and stability. Because the slicing is done through the log’s center, the resulting veneer has a very even, linear grain. The spacing between annual rings on the surface is minimal, yielding a consistent color and figure. This uniformity is visible in the veneer’s appearance and also translates to excellent dimensional stability.

Oak veneer with a radial (quarter-sawn) cut shows straight, parallel grain lines and a consistent texture. Such radial veneer has very uniform appearance and is highly resistant to warping or wear.

Radial veneer is resistant to external influences – it does not deform easily with changes in humidity or temperature and it wears well over time. In technical terms, radial-cut wood has a much lower tendency to shrink or swell compared to other cuts. For example, quarter-sawn oak boards have a shrinkage coefficient of about 0.19% (and swelling about 0.20%) in the radial direction, which is roughly half the values for tangentially cut wood. In other words, radial veneer will undergo only about half the dimensional change that tangential veneer will under moisture fluctuations. This superior stability is a major advantage of radial veneer.

Another consequence of how little radial veneer moves is that it remains flat and true, so finished products using radial-cut veneer show less warping, gapping, or surface checking over time. This makes radial veneer especially suitable for applications where stability is critical (e.g. fine furniture, musical instruments, interior paneling in controlled climates).

However, radial cut is also less material-efficient. Only about 10–15% of the lumber from a log can be quarter-sawn (radially cut). A lot of the log is not used when slicing only along the radii. Because of this low yield, radial veneer is more expensive to produce. Manufacturers get fewer veneer sheets per log with this method, driving up the cost. Thus, radial (quarter-sawn) veneer tends to command a premium price in the market.

In woodworking standards, a board is classified as radial if the annual rings form a 60–90° angle with the board’s surface. Boards with ring angles from 45° up to ~60° are sometimes called semi-radial or rift-cut. These semi-radial veneers still exhibit many of the stability benefits of true radial veneer. In fact, the best performance is seen in material where the ring angle is close to 90° (pure radial).

Diagram illustrating radial vs. tangential cuts in a log based on the angle of annual growth rings.

Because radial veneer must be cut with the knife blade following the radius of the log, each veneer flitch is smaller and there is more waste. Despite the higher cost and lower yield, the technical advantages — superior strength, wear resistance, and low distortion — make radial cut veneer highly sought after for high-quality woodworking. In summary, radial veneer offers the best stability and durability, at the expense of being more expensive and relatively scarce.

Tangential Cut Veneer

Tangential-cut veneer (flat-sawn veneer) is cut parallel to the growth rings, rather than through the center. This method yields a very pronounced grain pattern on the veneer. Tangential veneer often displays the familiar “cathedral” or wavy grain pattern of wood, with arched figures formed by the annual rings. This gives a richer, more dramatic texture which many find visually appealing. For example, flat-sawn oak veneer shows sweeping arches and oval shapes in the grain (as shown below).

Oak veneer with a tangential (flat-sawn) cut, showing the characteristic arched or “cathedral” grain pattern of the growth rings. This vivid texture is a hallmark of tangentially cut veneer.

Tangential veneer typically has a less uniform appearance than radial veneer. The color and grain can vary more across the sheet, and features like growth ring curves, knots, or pores are more pronounced. Additionally, tangentially cut wood is less dimensionally stable. The shrinkage and swelling coefficients for tangential cut boards are higher – roughly double those of radial cut. In practical terms, this means tangential veneer is more prone to expansion or contraction with humidity changes, and thus woodworkers need to account for potential movement. Tangential veneer surfaces might experience slightly more warping or gaps if the environment fluctuates significantly, compared to radial surfaces which remain comparatively stable.

On the other hand, tangential cut veneer is much more economical. Because a log can be sliced tangentially with minimal waste (cutting parallel to the rings yields wider sheets and more veneer per log), the yield is higher and cost per square foot of veneer is a bit lower. In fact, flat-sawing is the most common way lumber is cut precisely because it maximizes material utilization. Thus, tangential veneer is readily available and budget-friendly, making it a practical choice for many projects where cost is a factor.

In summary, tangential veneer offers bold, decorative grain patterns and affordability, at the cost of greater movement and slightly reduced structural uniformity. It is ideal when a visually interesting wood figure is desired and when the application can accommodate a bit of dimensional change.

Conclusion

Both radial and tangential veneers have their place in woodworking. Radial (quarter-sawn) veneer is prized for its straight grain, consistency, and superior stability – making it suitable for high-end, precision applications. Tangential (flat-sawn) veneer, with its striking grain patterns, is often used for its beauty and economic advantages, especially in decorative surfaces. An understanding of these cut types helps professionals choose the right veneer for the job, balancing aesthetic preferences with performance requirements.

Ultimately, the choice between radial and tangential veneer will depend on the priorities of a project. When stability, durability, and a uniform look are paramount, radial veneer is the top choice. When a bold wood texture is desired (and a little movement is acceptable), tangential veneer may be preferred. By selecting the appropriate cut, woodworkers and designers can ensure the finished product meets both the technical specifications and visual expectations for their application.